Nearly 1,500 oil and gas (O&G) rigs are located offshore across the globe, the largest share of which are in the North Sea and Gulf of Mexico. The recent trend in O&G industry is to install the subsea processing loads on the seabed for reducing the required space on the platform or even removing the platform altogether. The subsea processes (or subsea factory) include gas compression, boosting, water injection, and separation. Typical power consumption of the Subsea loads is in the range of 5-300 MW, traditionally supplied by local gas turbines or diesel generators. Such power generation strategies have led to significant increase in greenhouse gas emissions. Also, the electric distribution system of O&G platforms is characterized as a weak electric grid, resulting in poor power quality, lower power factor, voltage and current harmonics, voltage notches, and common mode voltages. All these result in increased losses and also affect the long-term reliability.

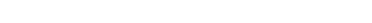

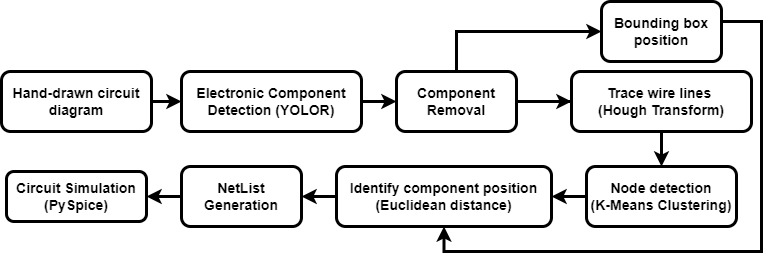

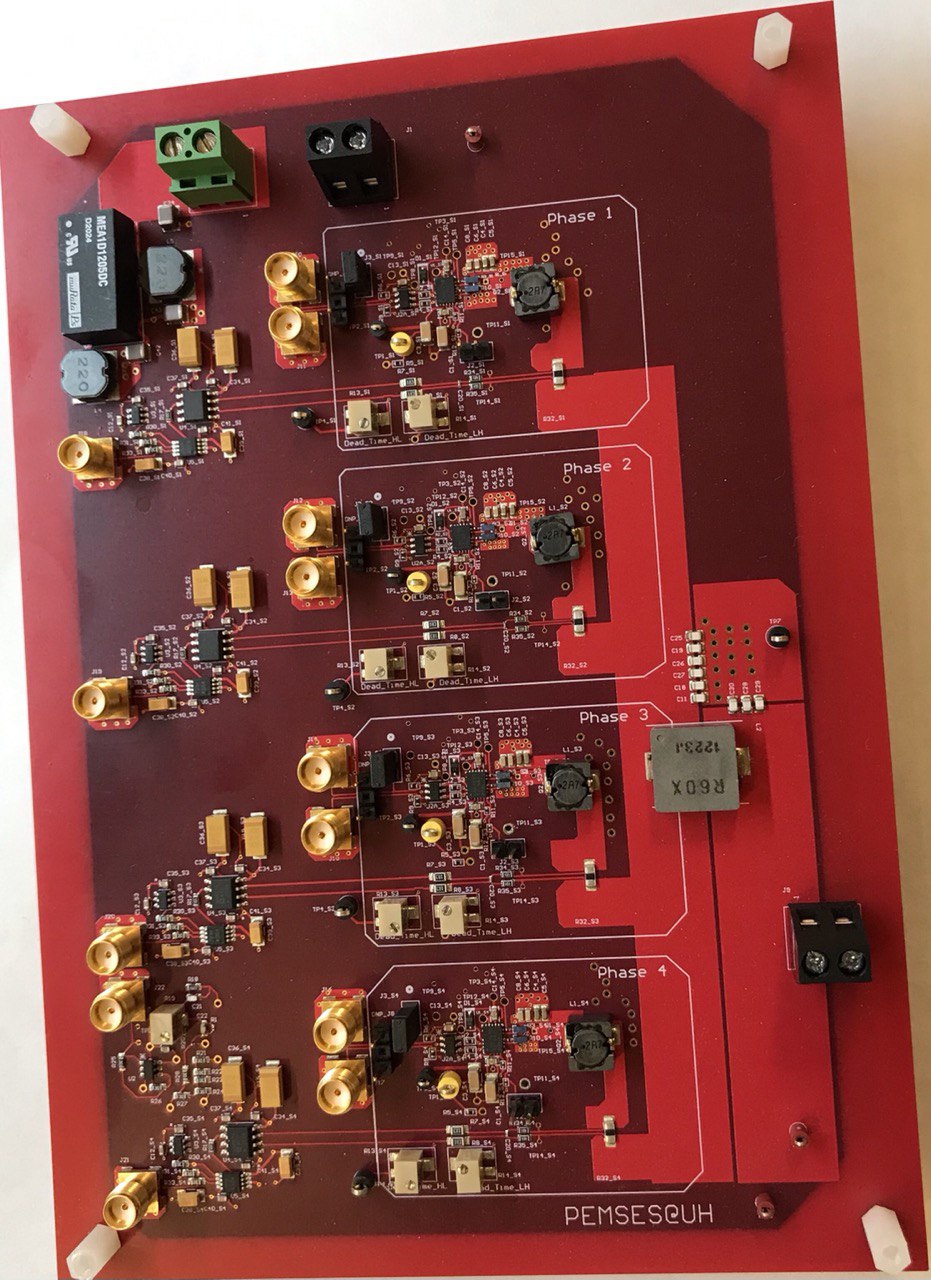

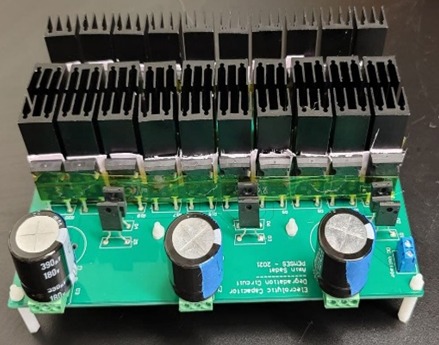

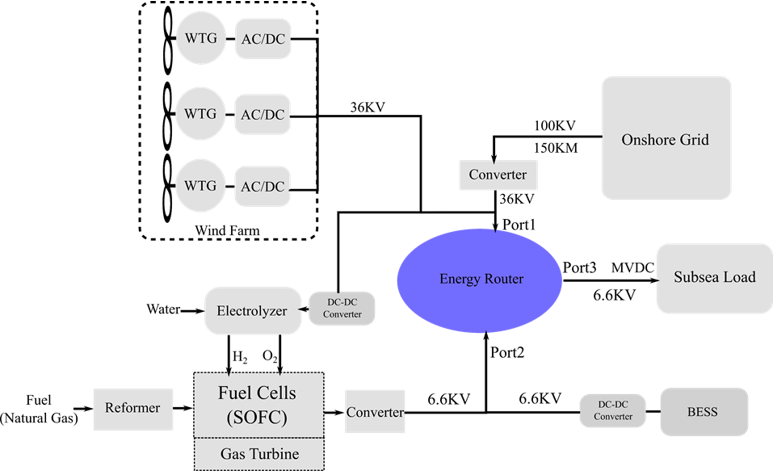

This project proposes a system of Multi-port Energy Routers using Intelligent Transformers (MERIT) to interface renewable resources and subsea O&G factories with the HVDC (or MVDC) Grid. In this project, we will investigate combining the energy from wind, wave, floating PV panels and fuel cell – based generators, all located near the subsea factories, to power the loads. Intelligent power converters, including solid state transformers (SSTs), are critical to enhance the power density, reliability and efficiency of the proposed MERIT system. SSTs enable seamless interconnectivity and interoperability between the various energy sources. SSTs support features such as instantaneous voltage compensation, power outage compensation, fault isolation, bi-directional power flow, etc. This research will also investigate how to optimally design and integrate SSTs into the MERIT system to have the best performance both during transient and steady state conditions. It is expected that widespread implementation of the proposed synergies can lead to over 50 % reduction in emissions.

As one of the foremost requirements of a subsea power delivery system is reliability, HVDC protection units must conform to extremely stringent specifications in terms of fault interruption time and fault level. However, a major challenge in the growth of DC power market is the lack of reliable protection against short-circuit faults. A fault in a DC system results in fast ramp up of the fault current. Moreover, DC fault current does not experience any natural zero-crossing. Therefore, DC circuit breakers (DCCBs) should be capable of fast fault quenching in order to prevent damage to the DC system and maintain grid resiliency. Additionally, a DCCB should operate with minimal power loss as a closed switch. Fault interruption using a DCCB causes enormous energy dissipation and voltage stress. If a DC fault current is 4-5 times higher than the rated DCCB, then it cannot work efficiently without expanding its components. Therefore, the use of a fault current limiter is essential, and the superconducting fault current limiter (SFCL) is the most promising choice together with a fast-switching DCCB in series. Resistive type superconducting fault current limiter (R-SFCL) is one of the most ideal, compact, small size current limiting devices to protect the power system and electrical equipment. It can limit the fault current effectively in power systems where CBs can work safely and prevent damage to the circuit components within several milliseconds.